Filtering Function of Ultrasonic Cleaners: A Sharp Tool for Improving Cleaning Efficiency

Browse Volume:779 Classify:Support

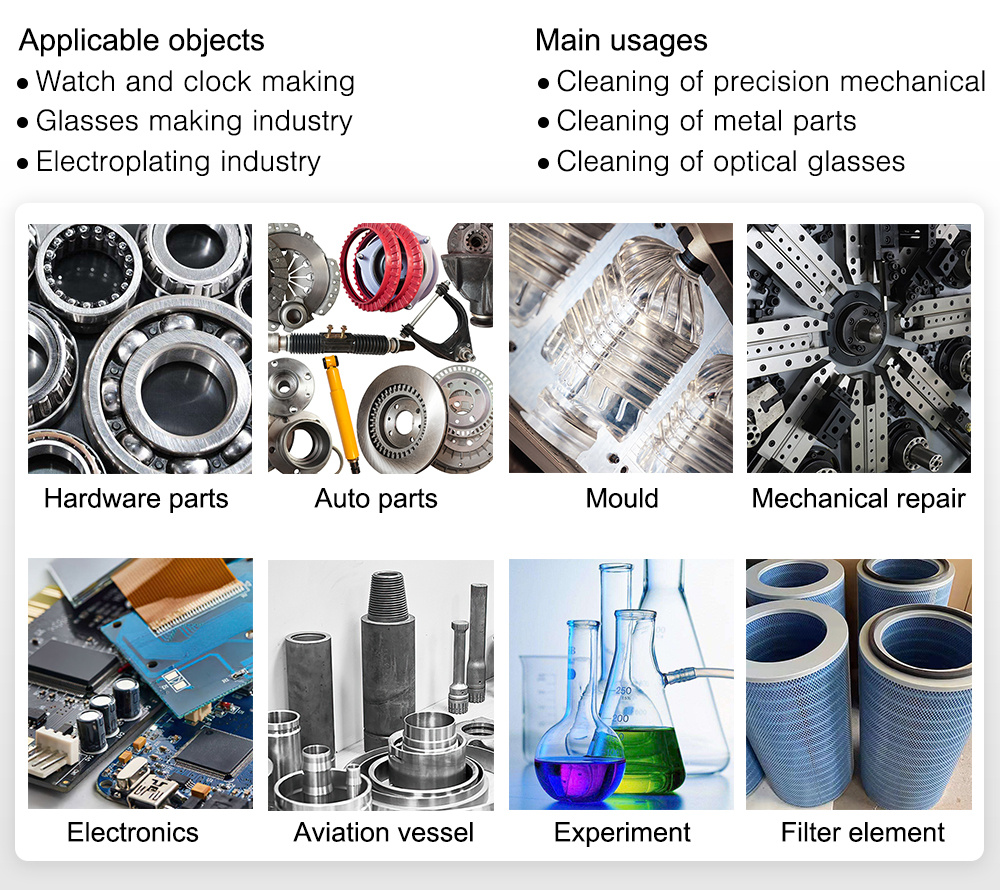

Ultrasonic cleaner is an advanced cleaning equipment that utilizes the principle of high-frequency ultrasonic vibration to thoroughly clean the dirt and pollutants on the surface of various objects. However, when using ultrasonic cleaners, adding filters can bring many advantages, further improving the cleaning effect and extending the service life of the equipment.

Firstly, adding filtration function can significantly enhance the cleaning effect. The ultrasonic cleaner rapidly removes dirt from the surface of an object through the explosive effect of producing small bubbles. However, during the cleaning process, the detached dirt and grease on the cleaned object may reattach to the surface of the object or suspend in the cleaning solution. By adding filters, these small dirt particles can be captured and filtered out, ensuring the cleanliness of the cleaning solution and making the cleaning effect more thorough.

Secondly, adding filtration function helps to extend the service life of the cleaning solution. Filters can effectively remove impurities and pollutants generated during the cleaning process, preventing them from contaminating the cleaning solution again. This can reduce the frequency of cleaning fluid replacement, save costs, and facilitate the management of maintenance personnel. At the same time, extending the service life of the cleaning solution is also environmentally friendly and reduces the discharge of waste liquid.

Thirdly, filters can protect cleaning devices and extend the service life of the equipment. The core components of ultrasonic cleaners, such as oscillators and heaters, are crucial and sensitive components. The entry of impurities and particles may damage these devices and affect the normal operation of the equipment. By adding filters, it is possible to effectively prevent impurities and particles from entering critical components, protect equipment, and reduce maintenance and replacement costs.

Ultrasonic cleaners with filtering function can bring multiple benefits:

Enhanced cleaning effect: Ultrasonic cleaners use small bubbles generated by high-frequency ultrasonic vibration to burst in the liquid, generating shock waves and eddies, which can quickly remove dirt and pollutants from the surface of objects. Adding a filter can effectively capture and filter out particles such as dirt and grease that have fallen off the cleaned object, maintain the cleanliness of the cleaning solution, and improve the cleaning effect.

Extending the lifespan of cleaning solution: The filter can effectively remove impurities and pollutants generated during the cleaning process, preventing them from contaminating the cleaning solution again. This can extend the service life of the cleaning solution, reduce the frequency and cost of replacing the cleaning solution.

Protecting cleaning devices: Filters can prevent impurities and particles from entering key components such as oscillators and heaters of the cleaner, reducing the risk of damage and extending the service life of the equipment.

Improving cleaning efficiency: By using a filter, impurities and pollutants in the cleaning solution are filtered out, and the working efficiency of the cleaner will be improved. The cleanliness of the cleaning solution is higher, which can better transmit ultrasonic vibration energy, improve cleaning speed and efficiency.

Overall, the filtering function of ultrasonic cleaners can improve cleaning efficiency, extend the service life of cleaning solution, protect cleaning devices, and improve cleaning efficiency. This is very beneficial for application scenarios that require efficient and thorough cleaning of objects.

GranboUltrasonic

GranboUltrasonic

Hello!