Efficient customized cleaning solution: 24-hour ultrasonic industrial cleaner

Browse Volume:771 Classify:Support

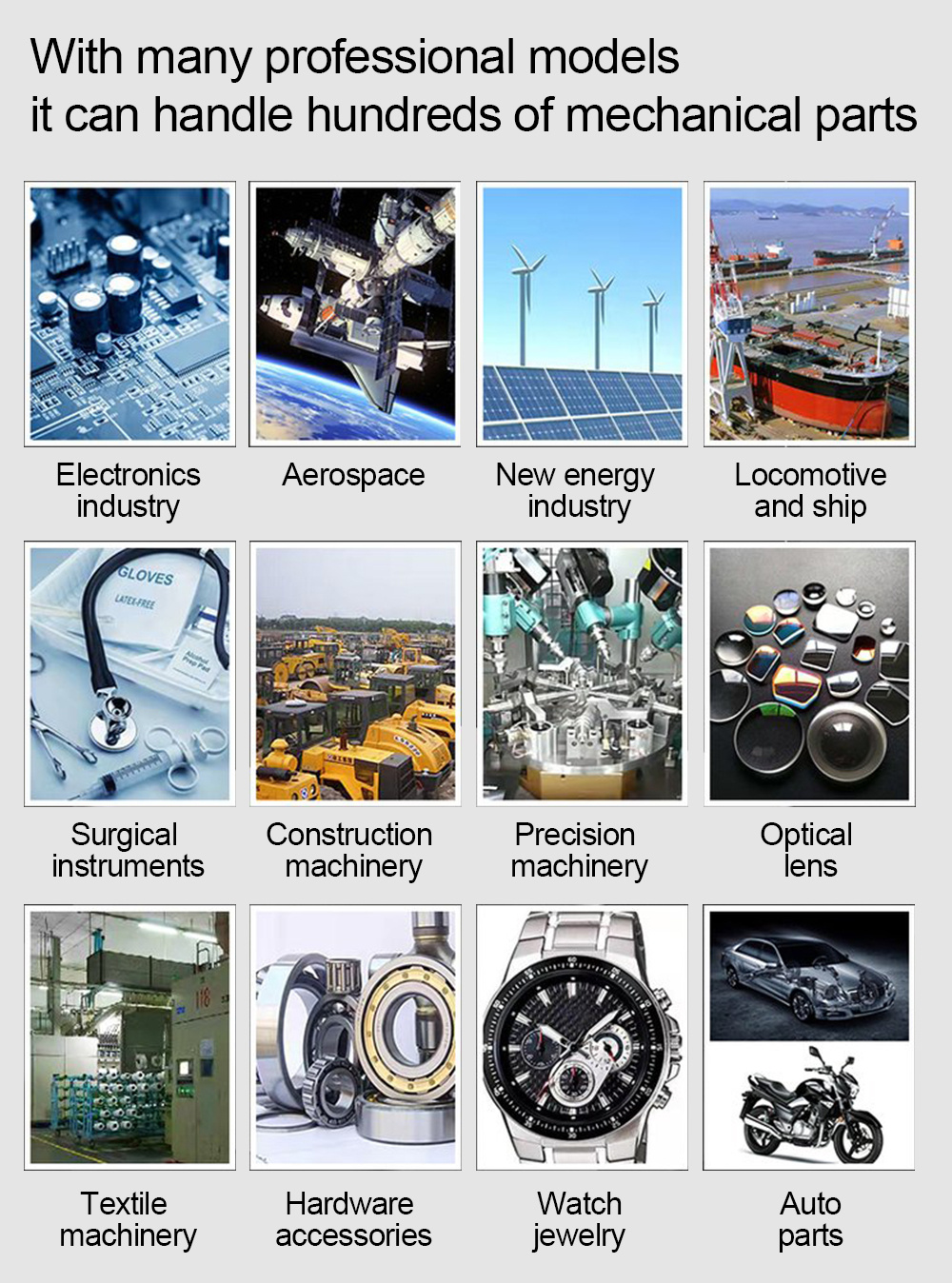

In modern industrial production, efficient cleaning is an important link to ensure product quality and production efficiency. In order to meet the cleaning needs of different industries, ultrasonic industrial cleaners have emerged with their customized and 24-hour uninterrupted working characteristics. This article will introduce this efficient cleaning solution and focus on its widespread application in cleaning automotive parts, hardware, motherboards, filter cartridges, and other fields.

With the continuous progress of industrial technology, various industries have put forward higher requirements for cleaning effectiveness and efficiency. Traditional cleaning methods often have low efficiency and poor cleaning effect, making it difficult to completely remove dirt and grease from the surface of parts. In order to solve these problems, ultrasonic industrial cleaners have emerged. Its customized characteristics enable it to adapt to the cleaning needs of various industries, providing efficient and reliable cleaning solutions.

The principle of ultrasonic cleaning technology:

Ultrasonic cleaning technology utilizes the mechanical effect of ultrasonic vibration and the blasting effect of small bubbles to transmit high-frequency sound waves to the surface of the cleaned object, in order to quickly separate, dissolve, and remove dirt. The vibration effect of ultrasound can expand and quickly contract small bubbles in the cleaning solution, forming a strong impact force and local high temperature, effectively removing dirt from the surface and small pores.

24-hour working characteristics and customization:

The ultrasonic industrial cleaner supports 24-hour uninterrupted operation without the need for shutdown cooling. Its independently designed heat dissipation system and sturdy and durable structure ensure the efficient and stable operation of the equipment. This enables continuous cleaning operations and significantly improves production efficiency. In addition, the cleaner also supports customization and can be adjusted and optimized according to different industries and cleaning needs to ensure the best cleaning effect.

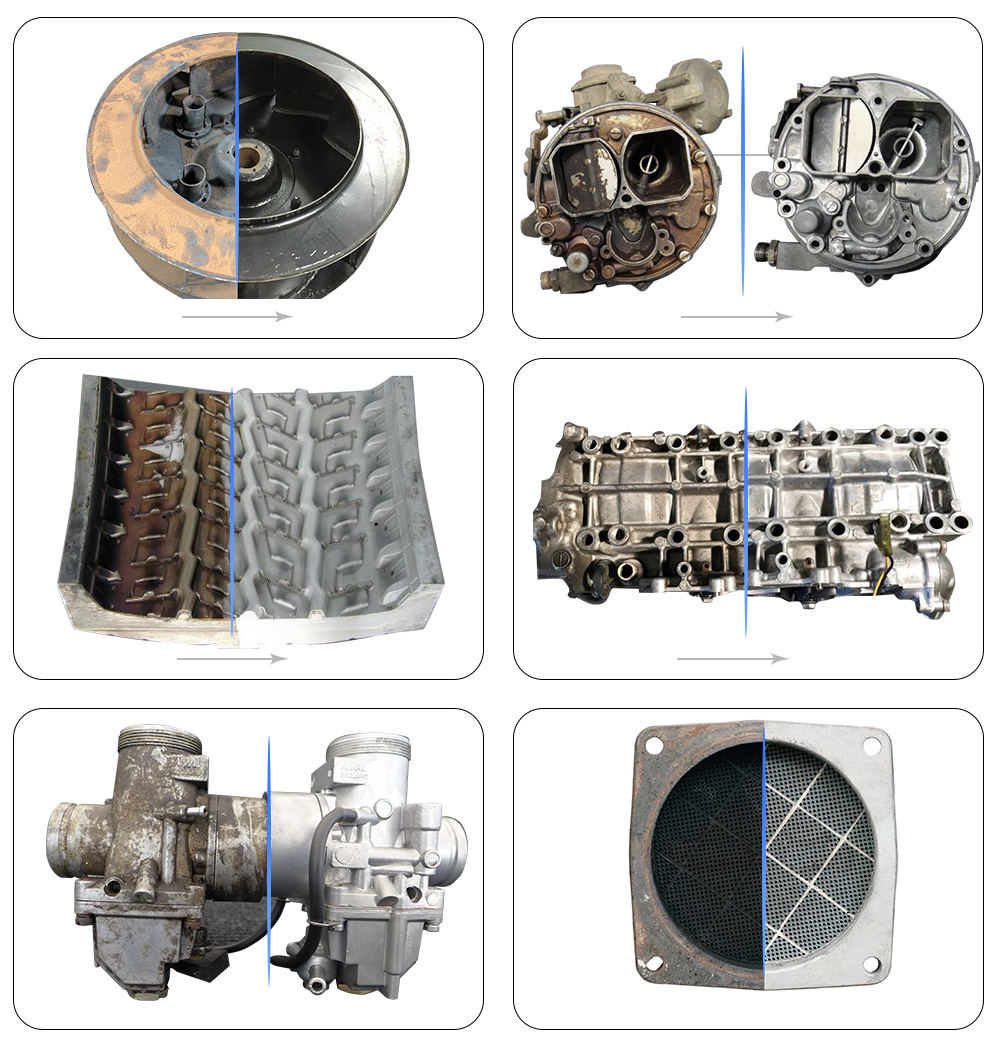

Ultrasonic industrial cleaners have significant advantages in cleaning automotive parts. It utilizes the principle of ultrasonic vibration to efficiently and thoroughly clean various automotive parts, restoring them to good working condition. The following will introduce the application and advantages of ultrasonic industrial cleaners in cleaning automotive parts.

Engine parts cleaning: Ultrasonic industrial cleaners can be used to clean engine parts, such as pistons, cylinder liners, crankshafts, etc. During the working process of engine components, various oil stains, carbon deposits, and metal chips will accumulate, affecting their normal operation and lifespan. Ultrasonic cleaners can quickly separate and dissolve dirt attached to the surface of components through ultrasonic vibration, achieving significant cleaning effects and ensuring the cleanliness and functionality of the components.

Fuel nozzle cleaning: The fuel nozzle is a key component in the engine combustion system, and its normal operation is crucial for engine performance. However, long-term use can cause fuel nozzle blockage or smaller nozzle aperture, affecting the fuel injection effect. The ultrasonic industrial cleaner can thoroughly clean the fuel nozzle, remove oil scale and carbon deposits inside the nozzle, restore its normal injection performance, improve combustion efficiency and fuel economy.

GranboUltrasonic

GranboUltrasonic

Hello!