How to glue ultrasonic transducer and ultrasonic wash tank

Browse Volume:1680 Classify:Support

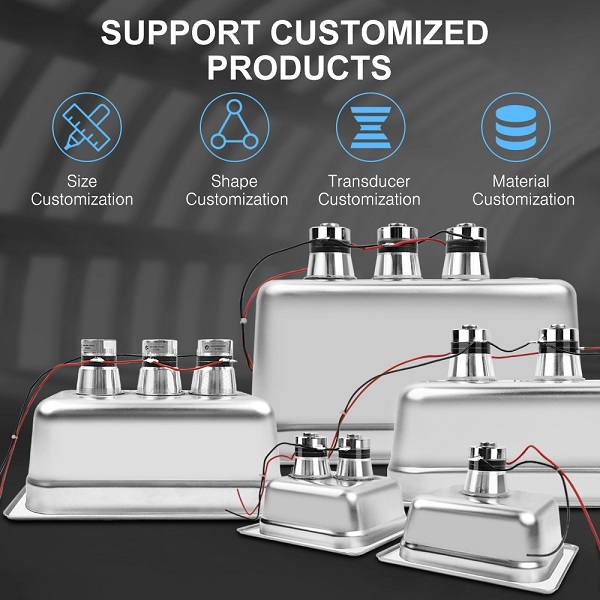

There are two types of transducers

No nail-type transducer is flat, adhesion with glue.

The nail transducer has a screw, installed by welding.

transducers model

Today we introduce you to how to glue ultrasonic transducers and ultrasonic wash tank

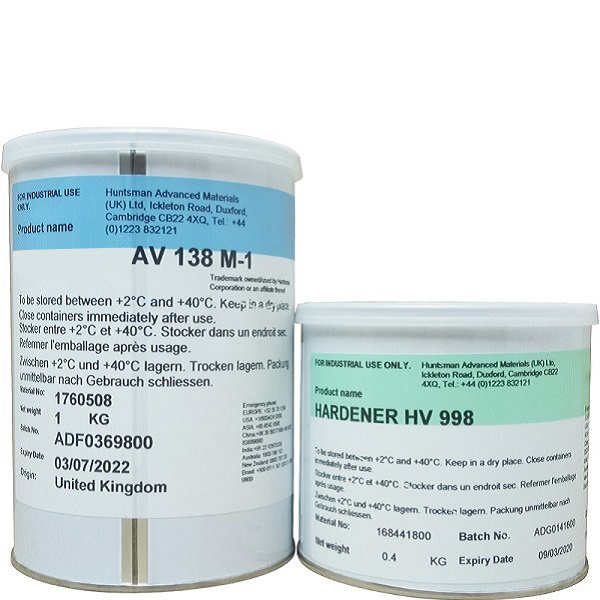

138/998 / bond ultrasonic transducer /epoxy glue AB glue is commonly used in ultrasonic cleaning equipment.

You also can see the other keywords:

AV138M HV998 Epoxy AB Glue Ultrasonic Vibrator Transducer Magnetic Tile Glue

AV 138M-1 HV 998 ultrasonic transducer AB glue

AV 138M-1 / Hardener HV 998-1 – Manufacturer Huntsman

AV 138M with Hardener HV 998 is a two component, room temperature curing paste adhesive of high strength. When fully cured the adhesive will have excellent performance at elevated temperatures and has high chemical resistance. It is suitable for bonding a wide variety of metals, ceramics, glass, rubbers, rigid plastics an other materials, and is widely used in many industrial applications where resistance to aggressive or warm environments are required. The low out gassing makes this product suitable for specialist electronic telecommunication and aerospace applications.

AV 138M with Hardener HV 998 is a two component, room temperature curing paste adhesive of high strength. When fully cured the adhesive will have excellent performance at elevated temperatures and has high chemical resistance. It is suitable for bonding a wide variety of metals, ceramics, glass, rubbers, rigid plastics an other materials, and is widely used in many industrial applications where resistance to aggressive or warm environments are required. The low out gassing makes this product suitable for specialist electronic telecommunication and aerospace applications.

Widely used in many industrial applications where resistance to aggressive or warm environments are required. The low out gassing makes this product suitable for specialist electronic telecommunication and aerospace applications.

AV 138M-1 HV 998 ultrasonic transducer AB glue

Key properties

• Excellent chemical resistance

• Temperature resistant to 140°C

• Thixotropic, gap filling paste

This bundle contains:

1x Araldite AV138M-1 Epoxy Resin – 1Kg Can

1x Araldite HV998-1 Epoxy Hardener – 400gm Tin

Features:

Low out gassing / volatile loss

Excellent chemical resistance

Temperature resistant to 120°C

Thixotropic, gap filling paste

Pretreatment

The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded.

At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprie-tary degreasing agents in order to remove all traces of oil, grease and dirt.

Low grade alcohol, gasoline (petrol) or paint thinners should never be used.

The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pick-ling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment

ultrasonic transducer glue wash tank

Application of adhesive

The resin/hardener mix is applied with a spatula, to the pretreated and dry joint surfaces.

A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint.

The joint components should be assembled and clamped as soon as the adhesive has been applied. An even contact pressure throughout the joint area will ensure optimum cure.

Mechanical processing

Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of adhesive.

We will be pleased to advise customers on the choice of equipment for their particular needs.

Equipment maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation.

If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Typical cured properties

Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lapjointing 114 x 25 x 1.6 mm strips of aluminium alloy.

The joint area was 12.5 x 25 mm in each case.

The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification.

Baking fixed transducer glue connection

Average lap shear strengths of typical metal-to-metal joints (ISO 4587) (typical average values)

Cure: 16 hours at 40°C and test at 23°C

Pretreatment – Sand blasting

Storage

Araldite® AV 138M-1 and Hardener HV 998-1 must be stored at room temperature provided the components are

stored in sealed containers. The expiry date is indicated on the label.

These products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with food-

stuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper not cloth towels should be used to dry the skin. Adequate ventilation of the working area is recommended. These precautions are described in greater detail in the Material Safety Data sheets for the individual products and should be referred to for fuller information.

ultrasonic transducer glue cleaning tank

Please note that when you DIY ultrasonic equipment:

The bottom of the transducers and the cleaning tank are clean and fat.

The cleaning tank is made of stainless steel.

The tank is filled with water when the transducer is working.

There is no bubble after bonding, otherwise, the generator will be short-circuited

Please do feel free to contact us if you have any questions or require any clarifications on our products, all size of ultrasonic cleaner parts available.

Wechat? WhatsApp: +86 19926489710

E: dean@granbo.com info@granboultrasonic.com dean@granbosonic.com

Granbo Ultrasonic

Granbo Ultrasonic

Hello!