Ultrasonic system and ultrasonic decontamination principle

Browse Volume:1104 Classify:Support

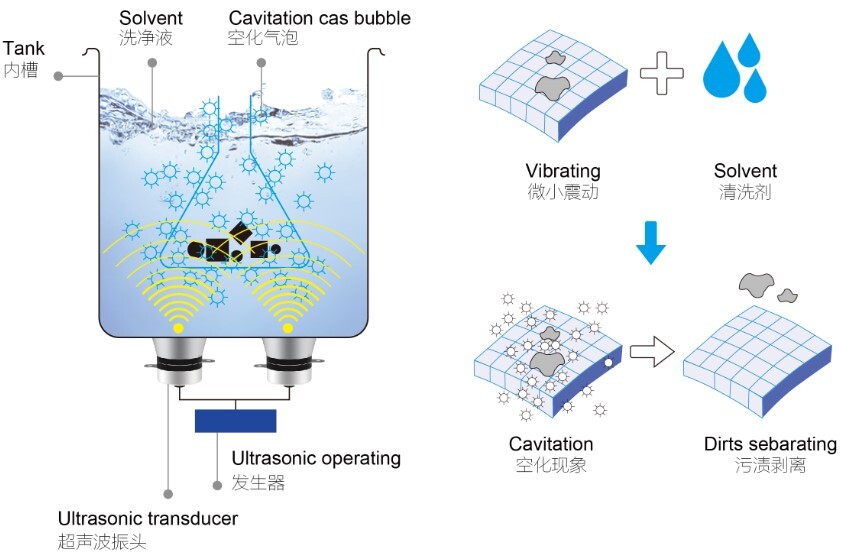

Ultrasonic cleaning uses the cavitation, acceleration, and direct inflow of ultrasonic in the liquid to, directly and indirectly, affect the liquid and dirt, so that the dirt layer is dispersed, emulsified, and stripped to achieve the purpose of cleaning. At present, cavitation and direct flow are more widely used in ultrasonic cleaning machines.

Ultrasonic Cavitation

Ultrasonic wave is a kind of sound wave whose frequency exceeds the range of human hearing by more than 20 kHz. The propagation of ultrasonic waves depends on the elastic medium. When it propagates, the particles in the elastic medium oscillate and transmit energy through the medium according to the propagation direction of the ultrasonic wave. This wave can be divided into longitudinal waves and transverse waves. In solids, both can be transmitted, while in gases and liquids, only longitudinal waves can be transmitted. Ultrasonic can cause particle vibration, and the acceleration of particle vibration is directly proportional to the square of ultrasonic frequency. Therefore, tens of kHz ultrasound will produce great force. When strong ultrasound propagates in liquid, acoustic cavitation will occur due to a nonlinear effect. The shock wave generated when the cavitation bubble is suddenly closed can generate thousands of atmospheric pressures around it. The direct and repeated impact on the dirt layer will destroy the adsorption between the dirt and the surface of the cleaning part on the one hand, and cause the damage of the dirt layer to separate from the surface of the cleaning part and disperse them into the cleaning solution on the other hand. The vibration of bubbles can also scrub the solid surface. Bubbles can also “drill” into cracks to vibrate and make dirt fall off. For oily dirt, due to ultrasonic cavitation, the two liquids are rapidly dispersed and emulsified at the interface. When the solid particles are wrapped by oil and adhere to the surface of the cleaning part, the oil is emulsified and the solid particles fall off. The so-called bubble itself will produce cavitation in the process of liquid circulation. It can make the surface of vibrating bubbles have a high-velocity gradient and viscous stress, and promote the destruction and falling off of dirt on the surface of cleaning parts. The high-speed microjet generated by ultrasonic cavitation on the solid and liquid surfaces can remove or weaken the boundary dirt layer, corrode the solid surface, increase the stirring effect, accelerate the dissolution of soluble dirt, and strengthen the cleaning effect of the chemical cleaning agent. In addition, ultrasonic vibration causes great vibration velocity and acceleration of particles in the cleaning fluid, and also makes the dirt on the surface of the cleaning parts subject to frequent and intense impact.

Ultrasonic principle

Factors affecting cleaning

Cleaning medium: ultrasonic cleaning is adopted. Generally, there are two types of cleaning agents, namely chemical solvent and water-based cleaning agent. The chemical action of the cleaning medium can accelerate the effect of ultrasonic cleaning. Ultrasonic cleaning is a physical action. The combination of the two functions can fully and thoroughly clean the objects according to the.

Power density: the higher the power density of ultrasonic, the stronger the cavitation effect, the faster the speed, and the better the cleaning effect. However, for precision objects with a high surface finish, long-term high-power density cleaning will produce cavitation and corrosion on the surface of the object.

Ultrasonic frequency: it is suitable for rough, dirty, and initial cleaning of workpieces. If the frequency is high, the ultrasonic directivity is strong, which is suitable for fine object cleaning.

Cleaning at high temperature: Generally speaking, ultrasonic has the best cavitation effect at 50 ° C ~ 60 ° C. The higher the temperature is, the more significant the effect is. It may fail at high temperatures. Generally, when the ultrasonic exceeds 85 ° C, the cleaning effect has deteriorated. Therefore, when ultrasonic cleaning is actually applied, the working temperature of 50 ° C ~ 70 ° C shall be adopted

Ultrasonic cleaning effect

GranboUltrasonic

GranboUltrasonic

Hello!