How to find the best ultrasonic generator manufacturer

Browse Volume:1097 Classify:Support

Granbosonic is a leader in the ultrasonic cleaning equipment industry and ultrasonic generator manufacturing, famous as high-power ultrasonic vibration plates and high-frequency ultrasonic rods manufacturer.

Ultrasonic generators

Looking for ultrasonic vibration plate manufacturers, customized high-power ultrasonic vibration plates, vibration rods, Granbosonic technology – can customize all kinds of high-power and high-frequency ultrasonic generators. It has been a powerful manufacturer for more than 10 years and a high-tech enterprise in Shenzhen. Its products are excellent. You are welcome to consult online at any time, quickly recommend ultrasonic vibration plates and vibration rods for you, and quickly provide you with parameters, picture sizes and quotations.

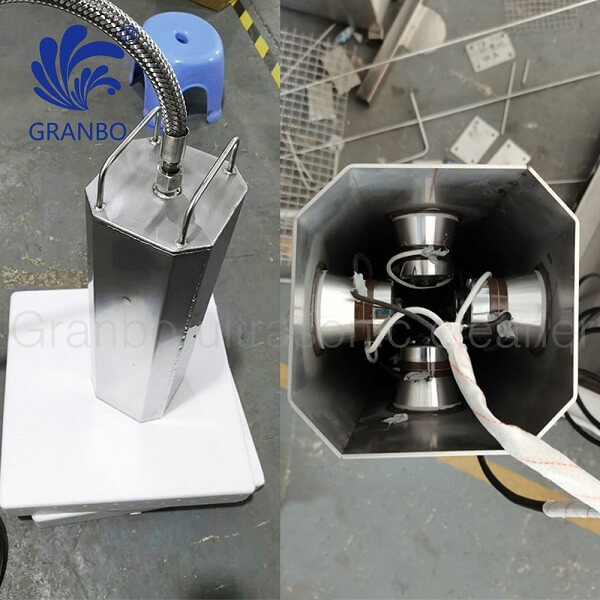

Ultrasonic generator with long rod

Functional features of Granbo ultrasonic vibration plate.

Cleaning: input cleaning, easy to carry, move and use;

Dispersion: dispersion and diffusion of carbon fiber or solvent;

Defoaming: it can discharge the air in the liquid;

Uniformity: uniform commissioning of chemical solvent drug samples;

Time adjustable: 1-99 minutes adjustable, normally open;

Adjustable power: 0-100% adjustable;

304 stainless steel shell: SUS304 stainless steel, thickened by 2.5mm;

Industrial vibrator: SUS304 stainless steel, mesh 10mm, steel bar reinforced;

Machine power line: Industrial thickened cable is adopted, which is safe and practical;

Generator power line: industrial power line, 3-pin grounding plug and anti-static design are adopted;

Heat dissipation of generator: the machine is equipped with heat dissipation fan + multi hole heat dissipation.

Ultrasonic generator with long rod operating

Multi frequency and dual frequency switching can be customized.

1. 28KHz 40KHz(common) 80KHz 120KHz(high) PCB Board

2. Dual Frequency PCB Board like 28KHz/40KHz,

3. 50W 60W 100W transducers

4. the transducer current is AC

There are two ways to achieve dual frequency mode.

1. Manual control

2. Auto control

For example, in one machine you can have a 28KHz and 40KHz PCB connected to the same transducer. But I assume that they cannot work at the same time. So we would have the 40KHz PCB working for 10 minutes, then stop, and then start the other 28KHz PCB.

Custom Ultrasonic Rod

Diamond shape ultrasonic vibrator

Application scope of Granbo ultrasonic vibration plate

Algae cleaning in dirty river water.

Swimming pool wastewater treatment.

Machinery industry: removal of antirust grease, cleaning of measuring tools, mechanical parts, engines and carburetors, dredging and cleaning of filters and filters, etc;

Surface treatment industry: oil and rust removal, phosphating, carbon deposition, oxide scale, polishing paste treatment, metal surface activation treatment before ion plating;

Instrument industry: high definition cleanliness of precision parts, cleaning before assembly, etc;

Electronics industry: cleaning of printed circuit board except for rosin, welding spot, high voltage electric shock, and other mechanical and electronic parts;

Medical industry: cleaning, disinfection, and sterilization of medical devices, cleaning of experimental utensils, etc;

Semiconductor industry: high definition cleaning of semiconductor chips;

Watch Jewelry Industry: remove oil sludge, dust, an oxide layer, polishing paste, etc;

Chemical and biological industry: carbon fiber diffusion, uniform solution mixing and accelerated reaction, cleaning, and descaling of utensils, etc;

Optical industry: degreasing, perspiration, and ash removal of optical glass, lenses, and utensils;

Textile printing and dyeing industry: rapid and uniform pH value soaking solution, cleaning of textile spindle and spinneret, etc;

Petrochemical Industry: cleaning and dredging of the metal filter screen, cleaning of chemical containers and exchangers, etc;

Other industries: photosensitive material manufacturing, papermaking, liquid defoaming (removing air from solution) in some food fields, etc.

real pics show

The application operation method of Granbo ultrasonic vibration plate

1. First connect the positive and negative poles of the vibrating plate with the generator

2. Put the vibrating plate into the container, and the vibrating plate shall be fully immersed in the liquid

3. Turn on the generator and the vibration plate starts to work.

Ultrasonic rod application

GranboUltrasonic

GranboUltrasonic

Hello!