Daily maintenance of industrial ultrasonic cleaning machine

Browse Volume:1125 Classify:Support

Daily maintenance of ultrasonic cleaning machine

1. Power supply: the power supply and power cord conforming to the equipment specification shall be used. The air switch dedicated to the cleaning machine must be installed in the power circuit of the user to cut off the power supply of the cleaning machine when necessary;

2. Grounding wire: the body and generator of the cleaning machine produced by our company will be equipped with a special grounding wire on its power lead, which is clearly distinguished from other wires. Because the equipment is in contact with water and corrosive (swelling) liquid level, it is easy to cause electric leakage. Please connect the grounding wire according to the safety requirements;

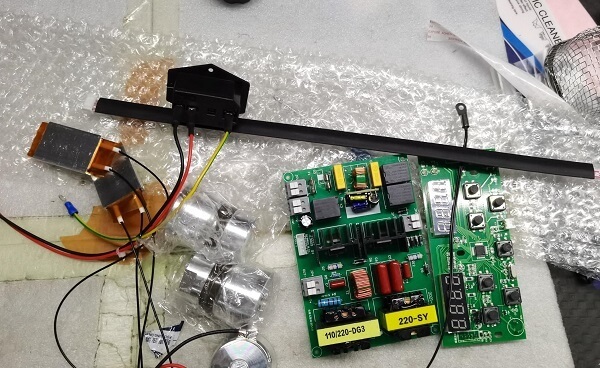

DIY Ultrasonic Parts

3. Noncombustible detergent shall be used for the equipment, and inflammable and explosive substances shall not be used as a detergent. When using the equipment, it is necessary to keep away from the occasions with inflammable and explosive substances. When users need to use some substances under special circumstances, they must consult our company to confirm safety and take corresponding safety protection measures;

4. No liquid or insufficient liquid level in the cleaning tank will cause irreversible damage to the equipment. When using, ensure that sufficient cleaning liquid is injected into the tank, otherwise, the relevant electric heater, pump, and ultrasonic vibrator may be damaged and may lead to fire and personal injury;

5. Pay attention not to splash water into the electrical control box and relevant electrical components, and keep away from water vapor, corrosive gas, dust, etc;

6. If the equipment is abnormal, please contact our company in time or check it with an experienced professional electrician after stopping the power supply;

7. The workpiece to be cleaned shall be hung with a washing basket or hanger with supporting feet and put into the tank for cleaning. It is forbidden to put the workpiece directly into the bottom of the tank for cleaning, otherwise, it may cause damage to the workpiece and cylinder bottom;

8. During equipment operation, there may be factors that may cause personal injury, such as high temperature, high voltage, electrified terminal surface of electrical components, movement of transmission mechanism, sudden pressure, and so on. Do not open the casing during operation to avoid operation without protection;

9. When the equipment is not used for a long time, please release the cleaning solution, dry the inner tank and surface, and protect them with a film to prevent the accelerated corrosion and aging of the equipment;

10. Keep the equipment workplace ventilated, dry, and clean, which is conducive to the long-term and efficient operation of the equipment and optimize the working environmental conditions;

11. If the cleaning solution is too dirty, it shall be handled in time. The dirt in the cleaning tank and liquid storage tank shall be cleaned regularly to keep the inside and appearance of the cleaning tank clean, which can improve its durability of the cleaning tank;

Industrial ultrasonic cleaner 2

Maintenance specification for industrial ultrasonic cleaner

1: For example, the industrial power supply is AC 380V. (three-phase four-wire)

2: First connect the signal line between the ultrasonic power supply and the cleaning tank. (check connection)

3: Add liquid into the cleaning tank at a height of about 300mm. The liquid in the liquid storage tank can reach half the height of the liquid storage tank, and the temperature is 40-55 degrees, which is the best.

Industrial ultrasonic cleaner 1

4: Put the workpiece to be cleaned into the cleaning tank and try not to directly contact the bottom. Do not strike the sidewall of the cleaning tank.

5: Set the time for the ultrasonic to work (note that the time cannot be zero), press the start button of the ultrasonic, and the ultrasonic starts to work.

6: The cleaning time is determined according to the degree of oil stain on the workpiece.

7: When the circulating filtration is closed, please close the filtered water outlet valve.

GranboUltrasonic

GranboUltrasonic

Hello!