How to troubleshoot industrial ultrasonic cleaning machine

Browse Volume:1126 Classify:Support

Troubleshooting operations of the industrial ultrasonic cleaning machines

Long time use of a device, but not its routine maintenance, then the equipment is easy to have fault problems. Today, take the Granbosonic industrial ultrasonic cleaning machine as an example to see how the cleaning equipment is handled and solved in case of failure.

Industrial ultrasonic cleaner 1

The transducer degumming of industrial full-automatic ultrasonic cleaning machine is usually the degumming condition caused by vibration after long-term use of ultrasonic cleaning equipment; After the use of cementation and screw fixation, there is usually no degumming fault, and due to the action of the screw, the vibrator will not fall from the vibration surface after degumming. Generally, the degumming state of the vibration surface can be judged by gently shaking the tail of the vibrator by hand.

Generally, the output power of the ultrasonic cleaning equipment power supply is normal after the degumming failure of the vibrator. However, due to the poor connection between the vibrator and the vibrating surface, the vibration effect of the vibrating surface is not good. If the ultrasonic power supply cannot be released due to energy for a long time, the vibrator of the cleaning machine will be burned out. Therefore, it is troublesome to solve the degumming fault of the vibrator. Therefore, in daily application, pay attention to avoid touching the surface of the vibrator to avoid degumming fault.

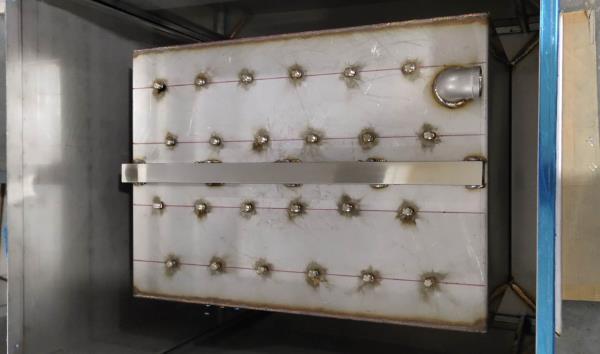

When the vibrator of the transducer is ignited, the ceramic material will be broken. You can check it with the naked eye and a megger. Usually, as an emergency measure, you can cut off individual damaged vibrators without affecting the normal use of other vibrators.

Industrial ultrasonic transducer

If the vibrator of the ultrasonic cleaning machine is damp, there will also be a series of fault problems. In its judgment of the dampness of the vibrator, we can use a megger to check the plug connected to the transducer. Judge by the insulation resistance value after inspection; Usually, the insulation resistance will exceed 5 trillion euros. If the insulation resistance value cannot be reached, it indicates that the transducer is wet. The whole transducer can be blown dry to restore it to the normal resistance value.

In fact, for daily application, as long as the maintenance is done well, the occurrence of instrument failure can be avoided to a great extent, so as to avoid the number of maintenance, and then prolong the service cycle of the full-automatic ultrasonic cleaning machine.

Solutions to ultrasonic failure

Industrial ultrasonic cleaner 2

1. When the instrument is turned on, the intensity of the ultrasonic wave decreases

The frequency of ultrasonic is used to measure whether the host is within the normal frequency range. If the difference is too large, it can be recovered through the frequency modulation potentiometer of the frequency modulation mainboard. Observe the current of the ammeter. If the current is less than the rated current, check whether the ultrasonic vibration plate is damaged, whether the vibration plate is broken, the vibration plate is broken, the film is cracked, the connecting wire is short-circuited, etc.

2. When the instrument is turned on, ultrasonic wave available, but its power cannot be adjusted

It is necessary to check the thyristor of the cleaning machine to see whether it is short-circuited or needs to be replaced. Check whether the transistor T5 is damaged and replace it.

Industrial ultrasonic cleaner 3

3. Open the instrument without ultrasonic

After the instrument is turned on, there is no ultrasonic response, the power switch indicator is not on and the fan does not rotate. Check the power supply of the ultrasonic cleaning machine to see whether it is plugged in, whether the power switch is damaged and whether the fan is damaged.

GranboUltrasonic

GranboUltrasonic

Hello!