Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Organizations that use medical devices and surgical tools can rely on ultrasonic cleaning technology to achieve high levels of disinfection and decontamination more thoroughly, safely and effectively. Ultrasound effectively cleans medical instruments and surgical tools that have hard-to-reach internal access, heavily soiled external surfaces, and complex tooling prior to sterilization. Ultrasonic cleaning saves time, is safe and thorough, and extends the life of expensive equipment without the use of abrasives or harsh chemicals that can scratch or damage delicate and highly processed objects.

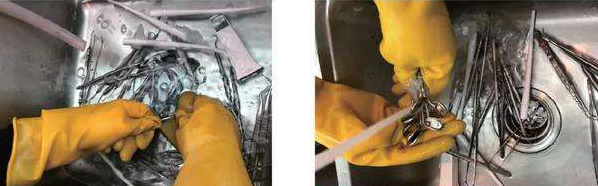

Industrial ultrasonic cleaner makes it easier to remove blood and tissue residues from surgical instruments below.

Ultrasonic cleaning saves time and money:

Functions

Optional function, cleaning + rinsing / cleaning + drying

With filtration system ,recycle and store detergent, ensure excellent cleaning result ,save cost

Parameter

The CDC, WHO and professional medical and dental associations stress the importance of thoroughly cleaning, then disinfecting or sterilizing reusable medical, dental and surgical instruments.

As pointed out in our post on cleaning dental instruments the process should start immediately so that blood and other matter do not dry on the instruments.

Carefully wiping gross contaminants from the instruments then placing them in an enzyme soak is a good first step before the ultrasonic cleaning process.

Ultrasonic energy is far superior to manually scrub these instruments because the microscopic bubbles are able to penetrate small cracks and crevices to blast away contaminants unreachable by manual processes. Moreover, the chances of personnel receiving cuts or puncture wounds are greatly reduced.

Cleaning procedures should follow the recommendations of professional associations along with those of ultrasonic equipment manufacturers and suppliers of cleaning solutions formulated for medical and surgical instruments.

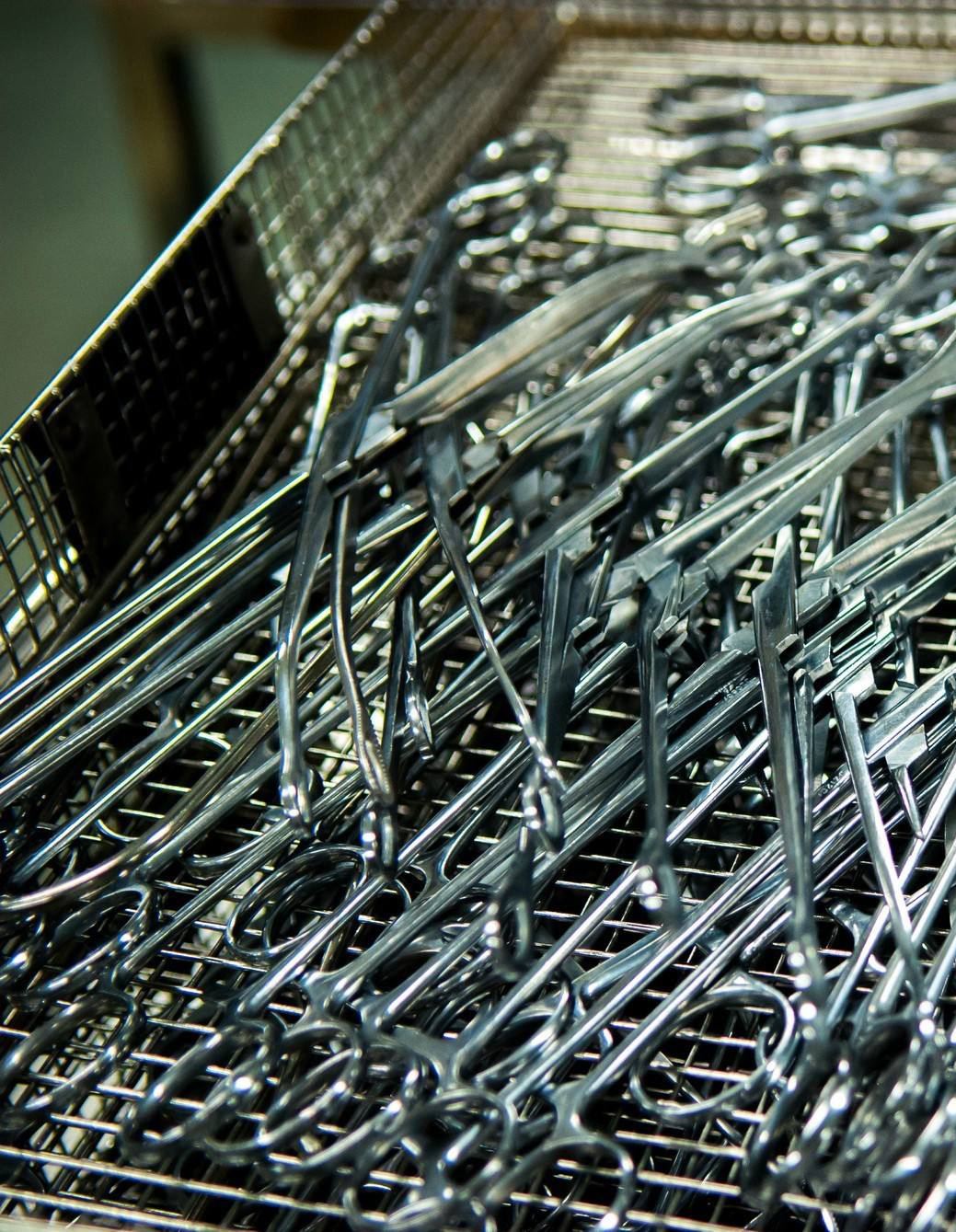

In general, however, disassembling instruments will help cavitation reach more surface areas. Fine mesh baskets are available to hold small parts. Clean instruments of similar composition in each cleaning cycle. Avoid cleaning chromium-plated instruments by sonic energy.

After the ultrasonic cleaning cycle instruments are ready for disinfecting or sterilizing.