The factors affecting ultrasonic cleaning effect: frequency, power, time, temperature, solutions

Browse Volume:1183 Classify:Support

This guide describes the principle and advantages of ultrasonic cleaning, the effect factors of ultrasonic cleaning results, the composition of equipment, application, and progress of ultrasonic cleaning technology are introduced.

Mechanism of ultrasonic cleaning machine technology:

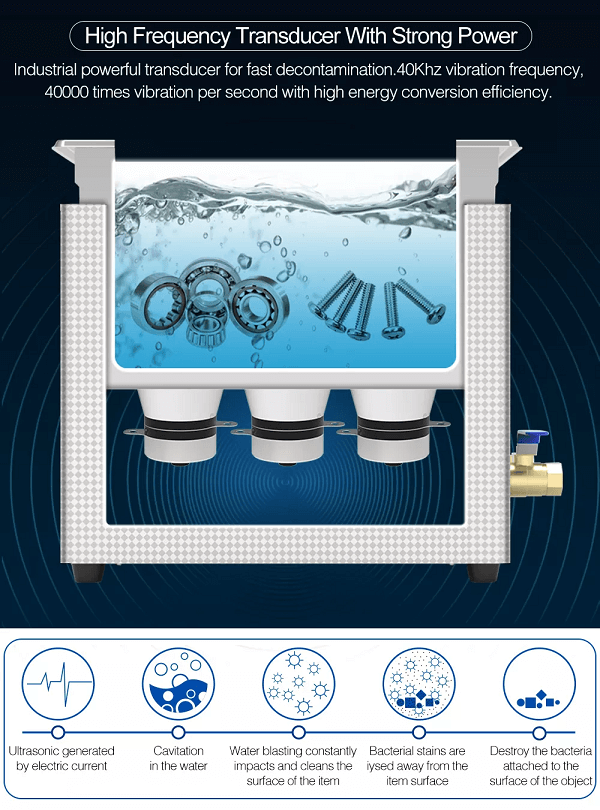

The principle of the ultrasonic cleaning machine is that the high-frequency oscillation signal sent by the ultrasonic generator is converted into high-frequency mechanical oscillation through the transducer and transmitted to the medium-cleaning liquid. The ultrasonic wave radiates to the cleaning liquid in a dense and alternating manner, causing the liquid to flow and produce tens of thousands of tiny bubbles. These bubbles form and grow in the negative pressure area where the ultrasonic wave propagates longitudinally, and close rapidly in the positive pressure area, In the process of this so-called “cavitation” effect, the bubble closure may become an instantaneous high pressure exceeding the past 1000 air pressures. The continuously generated high pressure is like a series of small “explosions” constantly impacting the object surface, causing the dirt on the object surface and in the gap to peel off rapidly. So as to achieve the comprehensive and clean cleaning effect of objects. Ultrasonic cleaning will not affect the material and accuracy of any object.

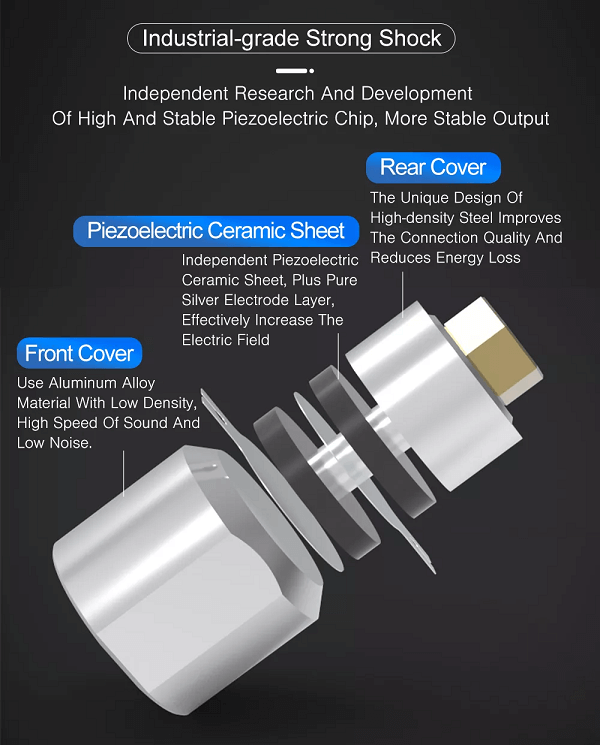

Piezoelectric Ultrasonic Transducer

Characteristics of ultrasonic cleaning technology:

Compared with other cleaning, ultrasonic cleaning has the advantages of a high cleaning rate, less residue, short cleaning time, and a good cleaning effect. Ultrasound can clean all the cleaned parts that can be immersed in liquid. It is not limited by the surface shape of the cleaning parts, such as deep holes, slots, and grooves. Can be cleaned. Because the ultrasonic generator adopts class D working amplification and the electroacoustic efficiency of the transducer is high, ultrasonic cleaning has high efficiency and energy saving. It is a cleaning technology with real high speed, high quality, and easy automation. If the cleaning agent adopts a non-ODS cleaning agent, it has the function of green environmental protection. Ultrasonic cleaning has a good cleaning effect on glass, metal, and other strong reflecting objects, but is not suitable for textiles, porous foam plastics, rubber products and other sound-absorbing materials.

Compared with various chemical, physical, electrochemical, and ultrasonic physical and chemical cleaning methods, ultrasonic cleaning has the following unique advantages: · it can quickly and thoroughly remove all kinds of dirt on the workpiece surface.

·It can clean precision parts with complex shapes such as cavities and grooves.

·No damage to the workpiece surface.

·Various cleaning agents can be used.

·It can be cleaned at room temperature or with proper heating (about 50 ℃).

·The integrated structure of the whole machine is easy to move.

·Save solvent, clean paper, energy, workplace, labor, etc.

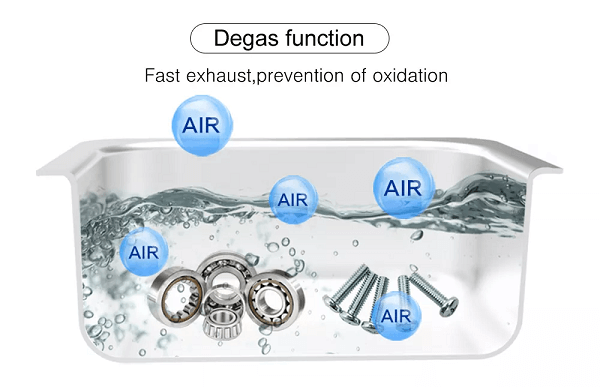

·Degas function: fast exhaust, prevention of oxidation

Ultrasonic Degas Function

Five features of Granbo ultrasonic cleaning machine:

1: Frequency

Choose different ultrasonic frequencies for different cleaning objects. For example, the cleaning of hardware, machinery, automobile and motorcycle, compressor and other industries or general objects with heavy pollution mostly adopts the cleaner with the frequency of 20kHz; The frequency of 40KHz is mostly used for optics, optoelectronics, circuit boards, and general laboratory utensils; 80kHz or higher frequency is mostly used for fine washing of computer microelectronic components, integrated circuit chips, silicon wafers, and wave films, which can remove micron and submicron dirt and do no damage to the cleaned samples.

Ultrasonic Frequency

2: Power

At present, the general standard products of our company have been set, and the production capacity is directly proportional to the ultrasonic power; High power products are mostly used for cleaning hardware, machinery, and other industries or general objects with heavy pollution.

3: Time

Different cleaning times should be set for different cleaning objects. Choosing the appropriate time (generally 10-20min) is conducive to better cleaning of the cleaned samples; A long time will lead to cavitation spots on the surface of the cleaned sample and affect the surface finish. If the time is too short, it will not be cleaned.

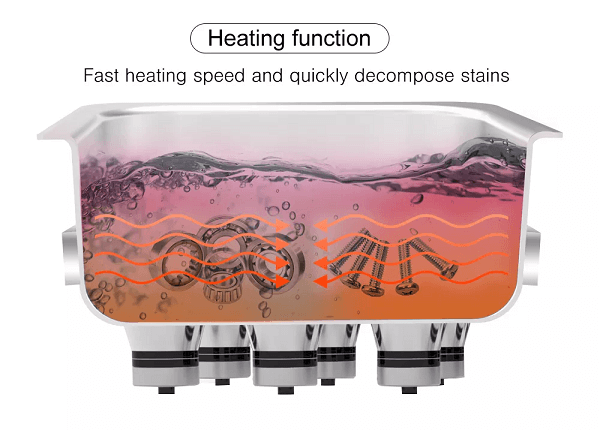

Heating Function

4: Temperature

Because the physical characteristics of each device are different, we should choose different cleaning temperatures when cleaning. For example, for grease, it is generally better to be above 50 ℃; For aluminum parts, when the ultrasonic cleaning machine works, it is generally appropriate to choose about 40 ℃. If the temperature is too high, oxidation spots will be formed; The burr below 15 ℃ should be generally selected. The unique constant temperature technology ensures that the cleaning objects will not be damaged when working in a constant temperature environment (the constant temperature of the company’s constant temperature products is 0-80 ℃, ± 2 ℃).

5: Cleaning fluid

Conventional cleaning solutions (media) include water-based solutions, alcohol, gasoline, and other organic solutions.

Modern ultrasonic cleaning agents are mixtures of various descaling agents, wetting agents, and other reactive components. There are many kinds of excellent and targeted cleaning agents to choose from. In order to achieve a proper cleaning effect and avoid the reaction between (the cleaning solution) and the object to be cleaned, the correct selection of cleaning agent is very important.

GranboUltrasonic

GranboUltrasonic

Hello!