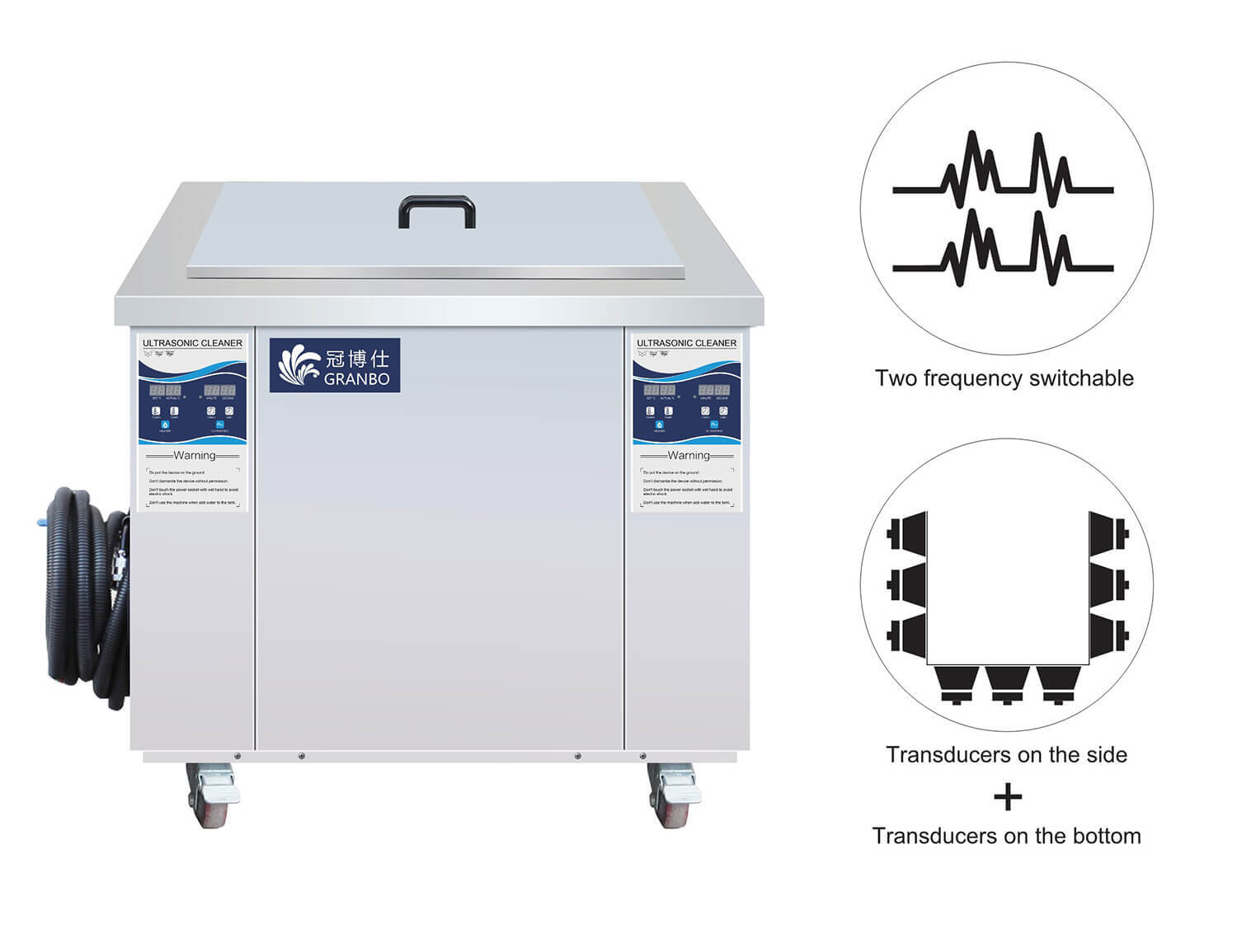

Why Ultrasonic Cleaning Works Best

Ultrasonic Cleaning through high-frequency vibration of the ultrasonic transducer to drive the oscillation of water or other liquid, so that more vacuum micro-bubbles are generated in the solution, and bubbles in the process of increasing the implosion, resulting in thousands of pressure impact strength, constantly impacting on the surface of the object to peel off the dirt. Therefore, ultrasound cleaning has microporous permeability and super peelability, so it is more efficient and energy-saving than traditional cleaning.

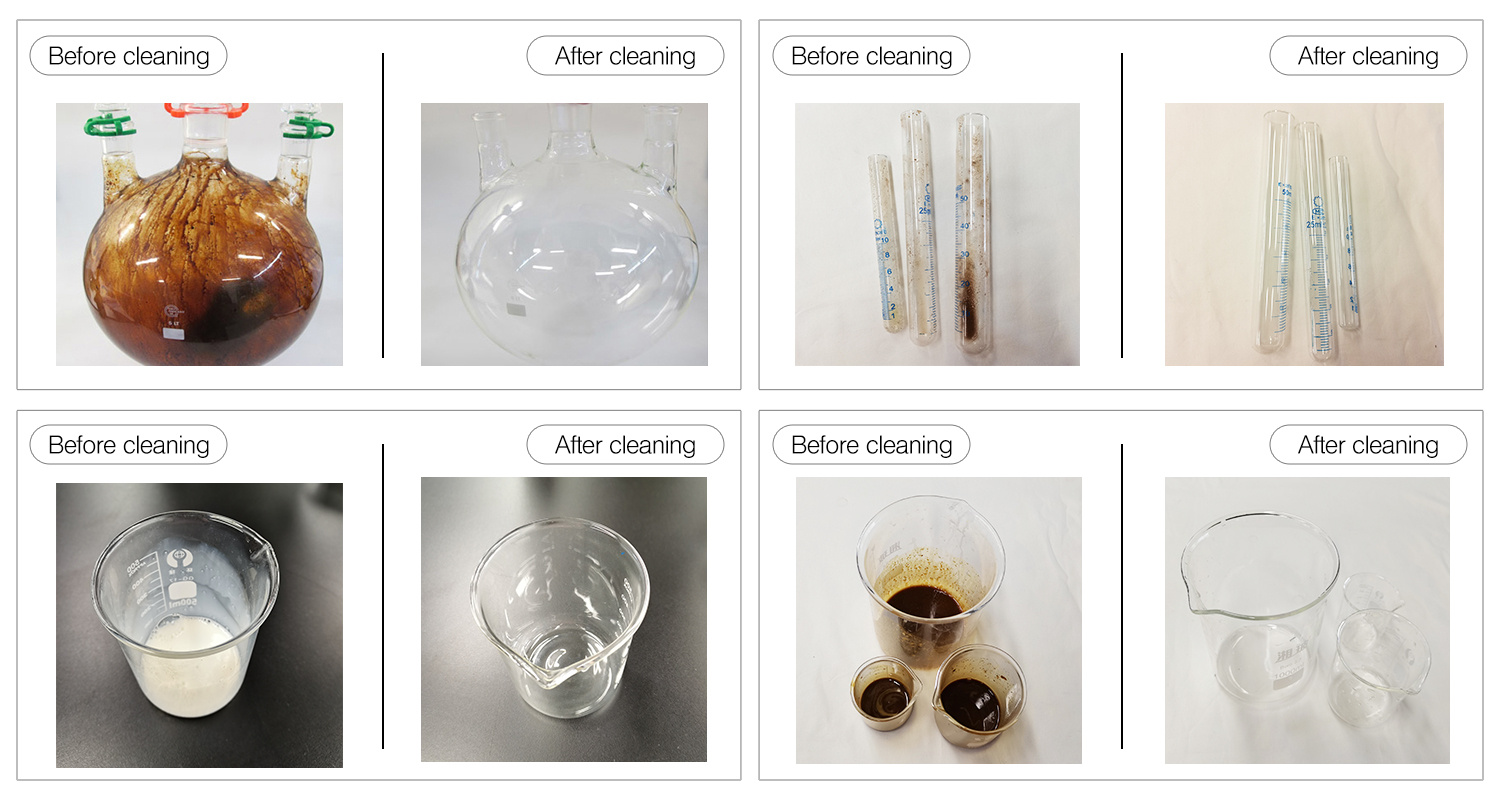

Cleaning Laboratory Glassware

Cleaning laboratory glassware such as flasks, graduated cylinders, burettes and pipettes require careful handling to avoid breakage. Lab glassware of complex shape is also difficult to clean.

Using an ultrasonic cleaner instead of manual washing and lab glassware washing machines not only can reduce breakage and associated replacement costs but also delivers a thorough cleaning job thanks to the power of cavitation action.

GranboUltrasonic

GranboUltrasonic