Expanding Industrial Horizons: Key Applications and Integration of Ultrasonic Cleaning

Browse Volume:7 Classify:Support

The Growing Role of Ultrasonic Cleaning in Modern Industries

Ultrasonic cleaning technology has seen widespread adoption across various industries, offering an efficient, precise, and environmentally friendly method for removing contaminants from a wide range of materials. This advanced cleaning method utilizes high-frequency sound waves to create cavitation bubbles in a liquid solution, effectively dislodging dirt, grease, and other impurities from surfaces, even in hard-to-reach areas. As industries seek more sustainable and high-precision cleaning methods, ultrasonic cleaning continues to gain traction due to its ability to enhance efficiency while reducing reliance on harsh chemicals and manual labor.

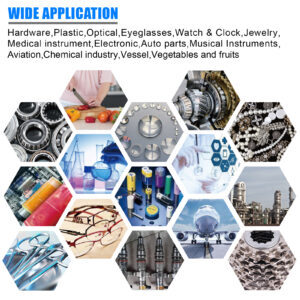

Core Application Scenarios of Ultrasonic Cleaning

The versatility of ultrasonic cleaning has led to its application in numerous fields, from delicate electronics to large-scale industrial equipment. Below are some of the most significant application areas where ultrasonic cleaning plays a crucial role.

1. Medical and Healthcare Equipment

Sterilization and cleanliness are of utmost importance in the medical field, making ultrasonic cleaning an essential technology for hospitals, laboratories, and dental clinics. Instruments such as scalpels, forceps, endoscopes, and dental tools require thorough cleaning before sterilization to eliminate microscopic contaminants.

- Advantages:

- Non-invasive and non-damaging to sensitive instruments

- Effectively removes biological residues

- Reduces the risk of cross-contamination

2. Electronics and Semiconductor Industry

Electronic components, including printed circuit boards (PCBs), microchips, and connectors, are highly sensitive to contaminants like dust, flux residues, and oils. Ultrasonic cleaning ensures that these delicate parts remain free from impurities, improving conductivity and performance.

- Advantages:

- Removes flux residues without damaging circuitry

- Cleans intricate and inaccessible areas

- Reduces rejection rates in manufacturing

3. Automotive and Aerospace Industry

Both the automotive and aerospace industries rely on ultrasonic cleaning for the maintenance and production of precision-engineered components. From fuel injectors to aircraft engine parts, ultrasonic cleaning provides a highly effective way to remove grease, carbon deposits, and metal shavings.

- Advantages:

- Enhances performance and longevity of engine parts

- Reduces the risk of mechanical failure

- Improves energy efficiency in industrial processes

4. Food Processing and Manufacturing

Hygiene and safety standards in the food industry demand meticulous cleaning processes. Ultrasonic cleaning is used to sanitize molds, conveyor belts, and processing equipment to eliminate bacterial contamination and food residues.

- Advantages:

- Ensures compliance with health and safety regulations

- Reduces the need for chemical detergents

- Enhances food product quality and consistency

Industrial Integration of Ultrasonic Cleaning Technology

As ultrasonic cleaning gains prominence, industries are increasingly integrating this technology into automated and large-scale production processes. The seamless incorporation of ultrasonic cleaning into industrial workflows has led to greater efficiency and cost savings.

1. Automation and Smart Cleaning Systems

With advancements in Industry 4.0, ultrasonic cleaning is being integrated into automated production lines, featuring:

- Robotic cleaning systems: Automated handling of components for precision cleaning

- Sensor-based monitoring: Real-time adjustments to optimize cleaning efficiency

- AI-driven diagnostics: Predictive maintenance to prevent equipment downtime

2. Eco-Friendly and Sustainable Cleaning Solutions

Ultrasonic cleaning is contributing to greener industrial practices by reducing water and chemical waste. Key sustainable innovations include:

- Biodegradable cleaning solutions: Minimizing environmental impact

- Water recycling systems: Reducing water consumption in industrial settings

- Energy-efficient ultrasonic transducers: Lowering overall power consumption

3. High-Precision Manufacturing Applications

Industries that require extreme cleanliness, such as semiconductor manufacturing and optics production, are leveraging ultrasonic cleaning in conjunction with advanced filtration systems to ensure contamination-free assembly processes. This integration is particularly vital in:

- Cleanroom environments: Where microscopic particles must be removed

- Nanotechnology fabrication: Ensuring material purity for advanced applications

- Aerospace engineering: Where precision cleaning impacts safety and durability

The Future of Ultrasonic Cleaning in Industry

The evolution of ultrasonic cleaning technology continues to push the boundaries of industrial applications. The integration of AI, automation, and eco-friendly solutions is making ultrasonic cleaning a key component in modern manufacturing and maintenance processes. As industries strive for higher efficiency and sustainability, ultrasonic cleaning is poised to become an even more indispensable tool in the global industrial landscape.

References

- Mason, T. J., & Lorimer, J. P. (2002). Applied Sonochemistry: The Uses of Power Ultrasound in Chemistry and Processing. Wiley-VCH.

- Ensminger, D., & Bond, L. J. (2011). Ultrasonics: Fundamentals, Technologies, and Applications. CRC Press.

- Jegatheesan, V., & Shu, L. (2013). Removal of pharmaceutical residues in wastewater treatment: An ultrasonic approach. Water Research, 47(1), 351-368.

- Leighton, T. G. (1994). The Acoustic Bubble. Academic Press.

- Koda, S. (2012). Sonochemistry: Theory, applications, and uses in industrial processing. Journal of Ultrasonics, 52(3), 209-218.

GranboUltrasonic

GranboUltrasonic