Next-Gen Industrial Ultrasonic Cleaners: Revolutionizing Precision Cleaning

Browse Volume:29 Classify:Support

In manufacturing, automotive, aerospace, and medical industries, maintaining impeccably clean machine parts is non-negotiable. Traditional cleaning methods—scrubbing, chemical baths, or pressure washing—often struggle with intricate geometries and microscopic contaminants. The latest **industrial ultrasonic cleaners** have transformed this process, leveraging advanced cavitation technology to deliver unmatched precision, efficiency, and sustainability.

These next-generation systems are not just incremental improvements; they represent a leap forward in automation, energy efficiency, and adaptability. From AI-driven cleaning cycles to eco-friendly detergents, modern ultrasonic cleaners are setting new standards in industrial maintenance.

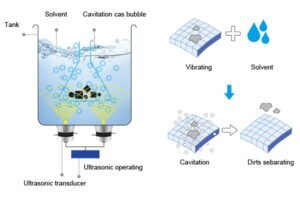

How Next-Gen Ultrasonic Cleaners Work

At the core of these machines is high-frequency ultrasonic cavitation, where sound waves (typically 20–400 kHz) generate microscopic bubbles in a liquid solution. These bubbles implode with tremendous force, creating a scrubbing effect that dislodges even the most stubborn grime—oil, grease, carbon deposits, and particulate matter—from the tiniest crevices.

Key Innovations in New Models:

– Multi-Frequency Systems – Adjustable frequencies allow switching between aggressive cleaning (low kHz for heavy grease) and gentle precision (high kHz for delicate parts).

– Pulsed Ultrasound – Reduces energy consumption while maintaining cleaning efficacy.

– Automated Fluid Management – Self-regulating detergent dosing and filtration systems extend solution life.

Unlike older models, these systems integrate IoT capabilities for remote monitoring, ensuring optimal performance without constant manual oversight.

Top 5 Advantages of Modern Ultrasonic Cleaning Technology

1. Unmatched Cleaning Precision

Legacy methods can’t compete with ultrasonic cleaners’ ability to reach internal channels, blind holes, and complex assemblies. This is critical for aerospace turbines, fuel injectors, and surgical tools.

2. Faster, More Efficient Operations

– Batch Processing – Large tanks clean multiple parts simultaneously.

– Reduced Labor – Automation minimizes hands-on scrubbing or rinsing.

– Shorter Cycle Times – Advanced transducers and heated solutions cut cleaning time by up to 50%.

3. Eco-Friendly and Cost-Effective

– Less Chemical Waste – Precision cavitation requires fewer harsh solvents.

– Water Recycling – Closed-loop systems filter and reuse water.

– Energy Savings – New inverters and pulsed modes lower power consumption.

4. Material-Safe Cleaning

Delicate materials (e.g., aluminum, titanium, or PCBs) won’t suffer abrasion or corrosion, unlike with mechanical methods.

5. Compliance with Industry Standards

Meets stringent requirements for medical sterilization (FDA), aerospace (AS9100), and automotive (IATF 16949).

Cutting-Edge Applications Across Industries

Automotive & EV Manufacturing

– Battery Component Cleaning – Removes machining oils from lithium-ion battery parts without damaging sensitive materials.

– Transmission Systems – Eliminates metal shavings and sludge from gears.

Aerospace & Defense

– Turbine Blade Maintenance – Cleans cooling holes inaccessible to brushes.

– Composite Materials – Gentle yet thorough cleaning of carbon-fiber components.

Medical & Dental

– Surgical Instrument Sterilization – Combines ultrasonic cleaning with autoclaving for infection control.

– 3D-Printed Implants – Removes residual powders from porous structures.

Electronics & Semiconductor

– PCB Degreasing – Flux removal without harming microcircuits.

– Wafer Cleaning – Ultra-high-frequency systems for nanoscale contaminants.

Additive Manufacturing

– Post-Printing Residue Removal – Clears support materials from intricate 3D-printed metal parts.

Choosing the Right Industrial Ultrasonic Cleaner

1. Tank Size & Configuration

– Benchtop Units – For small or precision parts (<10L capacity).

– Conveyorized Systems – High-volume production lines.

– Custom Tanks – Designed for oversized components like aircraft landing gear.

2. Frequency & Power Adjustability

– Low (20–40 kHz): Heavy grease, large parts.

– High (80–400 kHz): Delicate surfaces, micro-debris.

3. Smart Features

– IoT Connectivity – Real-time monitoring via smartphone.

– Self-Diagnostic Alerts – Notifies users of transducer issues or fluid depletion.

4. Sustainability Credentials

Look for:

– Closed-loop water systems.

– Biodegradable detergent compatibility.

– Energy Star® certifications.

5. Compliance & Safety

– Explosion-Proof Models – For flammable solvent use.

– CE/UL Certification – Ensures electrical safety.

The Future: AI, Robotics, and Green Tech

Emerging trends are pushing ultrasonic cleaning further:

– AI-Powered Optimization – Machine learning adjusts frequency/power in real-time based on part load.

– Robotic Integration – Automated arms load/unload parts for lights-out manufacturing.

– Nanobubble Technology – Enhances cavitation for submicron contaminant removal.

– Hydrogen-Based Cleaning – Experimental systems using H₂ for zero-waste residue breakdown.

As industries prioritize sustainability and precision, these innovations will redefine “clean” in industrial settings.

References

1. Leong, T., et al. (2021). “Advanced Ultrasonic Cavitation for Industrial Cleaning.” Ultrasonics Sonochemistry, 70, 105293.

2. FDA (2023). “Guidance on Medical Device Reprocessing.”

3. ASM Handbook (2022). “Surface Engineering for Cleanability.” Vol. 5.

4. Siemens Industrial Solutions. (2023). “IoT in Ultrasonic Cleaning Systems.” Whitepaper.

Industrial ultrasonic cleaners are no longer just tanks with buzzers—they’re intelligent, sustainable, and indispensable tools for 21st-century manufacturing. Whether upgrading legacy systems or investing in new tech, businesses that adopt these advancements will lead in quality and efficiency.

GranboUltrasonic

GranboUltrasonic