Title: Revolutionizing Industrial Cleaning: The Power of Ultrasonic Technology with Advanced Filtration Systems

Browse Volume:28 Classify:Support

In the fast-paced world of industrial manufacturing, maintaining the cleanliness and functionality of equipment is paramount. Traditional cleaning methods often fall short when it comes to precision and efficiency, especially for intricate components. Enter ultrasonic cleaning technology, a game-changer that has transformed the way industries approach cleaning. When combined with advanced filtration systems, ultrasonic cleaning becomes even more powerful, offering unparalleled results for a wide range of applications. This article explores the synergy between ultrasonic cleaning and filtration, highlighting its benefits, applications, and future potential.

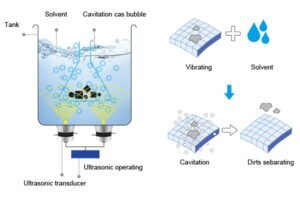

The Science Behind Ultrasonic Cleaning

Ultrasonic cleaning operates on the principle of cavitation, where high-frequency sound waves create microscopic bubbles in a liquid solution. These bubbles implode upon contact with surfaces, effectively dislodging dirt, grease, and other contaminants. This method is particularly effective for cleaning complex and delicate items, such as medical instruments, electronic components, and optical lenses, where traditional cleaning methods might fail.

The process is non-invasive and non-abrasive, making it ideal for materials that require gentle yet thorough cleaning. However, as contaminants are removed from the items being cleaned, they remain in the cleaning solution, which can reduce its effectiveness over time. This is where filtration systems come into play, ensuring that the cleaning solution remains clean and efficient.

The Role of Filtration in Ultrasonic Cleaning.

Filtration systems in ultrasonic cleaners are designed to remove particulate matter from the cleaning solution, preventing recontamination of the items being cleaned. By continuously filtering the solution, these systems maintain its effectiveness and extend its lifespan. There are several types of filters used in ultrasonic cleaners, including:

– Mechanical Filters: These capture larger particles and debris, often using mesh or porous materials.

– Activated Carbon Filters: These are effective at removing organic compounds and odors from the solution.

– Membrane Filters: These are used for fine filtration, capturing microscopic particles that other filters might miss.

The choice of filter depends on the specific application and the type of contaminants being removed. For example, a medical instrument cleaner might use a membrane filter to ensure sterility, while a jewelry cleaner might rely on a mechanical filter to capture larger debris.

Benefits of Ultrasonic Cleaning with Filtration Systems

The integration of filtration systems into ultrasonic cleaners offers several key advantages:

1. Extended Solution Life: By removing contaminants from the cleaning solution, filters reduce the need for frequent solution changes, saving time and money.

2. Improved Cleaning Consistency: Cleaner solutions lead to more consistent results, as there is no risk of recontamination.

3. Enhanced Efficiency: Filtration systems allow the ultrasonic cleaner to operate at peak performance for longer periods.

4. Environmental Benefits: Reducing the frequency of solution changes minimizes waste, making the process more eco-friendly.

5. Versatility: Filtration systems can be tailored to specific cleaning needs, making them suitable for a wide range of applications.

Applications of Ultrasonic Cleaning with Filtration

The combination of ultrasonic cleaning and filtration is used across various industries, each with its own unique requirements:

1. Medical and Dental: Surgical instruments, implants, and dental tools require thorough and sterile cleaning. Filtration systems ensure that the cleaning solution remains free of contaminants, meeting stringent hygiene standards.

2. Jewelry and Watches: Delicate items like rings, necklaces, and watch components benefit from the precision of ultrasonic cleaning, while filters prevent scratches caused by debris.

3. Electronics: Circuit boards and other electronic components can be cleaned without damage, and filters help remove tiny particles that could affect performance.

4. Automotive: Fuel injectors, carburetors, and other engine parts are often cleaned using ultrasonic technology, with filters ensuring that the solution remains effective.

5. Optics: Lenses, mirrors, and other optical components require spotless cleaning, and filtration systems help achieve this by maintaining a clean solution.

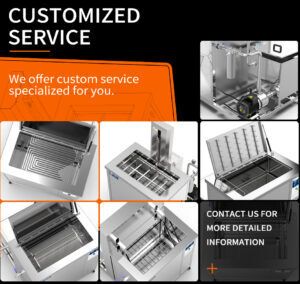

The image above shows an advanced ultrasonic cleaner equipped with a built-in filtration system. This device is ideal for industries requiring high levels of cleanliness and precision.

Choosing the Right Filtration System for Your Needs

When selecting an ultrasonic cleaner with a filtration system, consider the following factors:

1. Type of Contaminants: Identify the primary contaminants you need to remove, as this will determine the type of filter required.

2. Tank Size: Ensure the cleaner’s tank is large enough to accommodate your items while allowing space for the filtration system to operate effectively.

3. Flow Rate: The filtration system should have a flow rate that matches the cleaner’s capacity to maintain optimal performance.

4. Ease of Maintenance: Look for systems with easily replaceable filters and simple maintenance procedures.

5. Compatibility: Ensure the filtration system is compatible with the cleaning solutions you plan to use.

Investing in the right system will maximize the efficiency and longevity of your ultrasonic cleaner.

Maintenance and Care for Ultrasonic Cleaners with Filtration

Proper maintenance is essential to keep your ultrasonic cleaner and its filtration system functioning at their best. Here are some tips:

1. Regular Filter Replacement: Follow the manufacturer’s guidelines for replacing filters to ensure consistent performance.

2. Tank Cleaning: Periodically clean the tank to remove any buildup of contaminants that the filter may not catch.

3. Solution Monitoring: Check the cleaning solution regularly and replace it when necessary, even with a filtration system in place.

4. Inspect Components: Regularly inspect the ultrasonic transducers, filters, and other components for signs of wear or damage.

By maintaining your equipment properly, you can extend its lifespan and ensure it continues to deliver high-quality results.

The Future of Ultrasonic Cleaning with Filtration

As technology advances, we can expect further innovations in ultrasonic cleaning and filtration systems. Potential developments include:

– Smart Filtration: Integration with IoT technology to monitor filter status and cleaning efficiency in real-time.

– Advanced Filter Materials: New materials that offer higher filtration efficiency and longer lifespans.

– Energy-Efficient Designs: Cleaners that consume less power while maintaining high performance.

– Customizable Solutions: Systems that can be tailored to specific industries or applications with modular filter options.

These advancements will continue to enhance the capabilities of ultrasonic cleaners, making them even more versatile and effective.

References

1. Jumpy Man Industrial Cleaning. (2025). Ultrasonic Industrial Cleaning. Retrieved from [http://www.jumpymansindustrialcleaning.com/](http://www.jumpymansindustrialcleaning.com/) .

2. Cleanosonic. (2025). Ultrasonic Cleaners and Cleaning Solutions. Retrieved from [https://www.cleanosonic.com/](https://www.cleanosonic.com/) .

3. Tullker. (2024). Application of Ultrasonic Cleaning Machine in Chemical Biology. Retrieved from [https://en.tullker.com/index.php?c=show&id=231](https://en.tullker.com/index.php?c=show&id=231) .

4. Shenzhen Lixinglong Machinery and Electrical Equipment Co., Ltd. (2019). Ultrasonic Cleaning Machin. Retrieved from [http://www.szlxljd.com/index_EN.html?chlang=&langid=2](http://www.szlxljd.com/index_EN.html?chlang=&langid=2) .

GranboUltrasonic

GranboUltrasonic