Enhancing Industrial Cleaning Efficiency: The Role of Ultrasonic Transducers

Browse Volume:40 Classify:Support

The Importance of Ultrasonic Transducers in Industrial Cleaning

In modern manufacturing and maintenance, industrial ultrasonic cleaners play a crucial role in removing contaminants from delicate and complex components. These advanced cleaning systems rely on ultrasonic transducers to generate high-frequency sound waves, creating microscopic bubbles that effectively dislodge dirt, grease, and residues. Understanding how ultrasonic transducers work and how they can be optimized is essential for improving industrial cleaning performance.

How Ultrasonic Transducers Function in Industrial Cleaners

Ultrasonic transducers serve as the core component of an industrial ultrasonic cleaner, transforming electrical energy into mechanical vibrations that generate cavitation in the cleaning solution. This process involves:

1. The Piezoelectric Effect: Driving Ultrasonic Vibrations

Most industrial ultrasonic transducers operate based on the piezoelectric effect, where piezoelectric materials such as lead zirconate titanate (PZT) expand and contract in response to an alternating electrical current. This creates:

- High-frequency vibrations that propagate through the cleaning liquid.

- Consistent cavitation bubbles that reach intricate surfaces.

- Minimal energy loss, improving overall efficiency.

2. Magnetostrictive Transducers: Heavy-Duty Alternatives

In industrial applications requiring robust cleaning power, magnetostrictive transducers offer an alternative solution. These transducers use ferromagnetic materials that change shape in response to a magnetic field, providing:

- Higher power output for demanding cleaning tasks.

- Greater durability under extreme conditions.

- Enhanced performance for removing stubborn contaminants like carbon deposits and metal oxides.

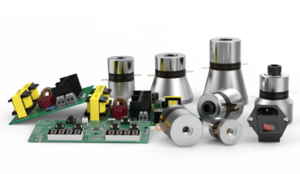

Essential Components of an Industrial Ultrasonic Transducer

Industrial ultrasonic transducers are designed for durability and efficiency, featuring several key components that contribute to their effectiveness.

1. Piezoelectric or Magnetostrictive Elements

The core element of an ultrasonic transducer determines its vibration frequency and power output. High-quality materials ensure optimal energy conversion and longevity.

2. Mounting System and Bonding Material

Transducers must be securely mounted to the ultrasonic cleaner’s tank or sonotrode to ensure effective transmission of sound waves. Strong bonding materials such as epoxy or soldering alloys are used to:

- Improve energy transfer.

- Minimize mechanical losses.

- Prevent detachment under high-intensity operation.

3. Backing Layer and Damping Material

The backing layer absorbs unwanted vibrations and reduces interference, ensuring that ultrasonic energy is directed efficiently into the cleaning liquid.

Factors Affecting the Performance of Industrial Ultrasonic Transducers

Several factors influence the efficiency and durability of ultrasonic transducers in industrial applications.

1. Frequency Selection for Specific Cleaning Applications

Industrial ultrasonic cleaners operate at different frequencies, typically ranging from 20 kHz to 200 kHz. The appropriate frequency depends on the type of contaminants and materials being cleaned:

- Low frequencies (20–40 kHz): Ideal for heavy-duty cleaning of large metal components, removing grease, rust, and carbon deposits.

- Mid-range frequencies (40–80 kHz): Suitable for general-purpose industrial cleaning, including automotive parts and electronic components.

- High frequencies (80–200 kHz): Used for precision cleaning of delicate items, such as medical instruments and semiconductor components.

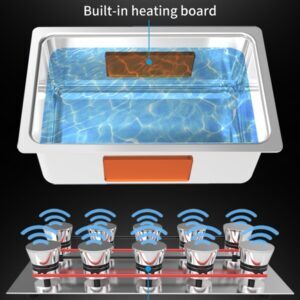

2. Power Density and Cavitation Intensity

Higher power density leads to stronger cavitation, which enhances cleaning efficiency but requires careful calibration to prevent damage to sensitive components. Factors that influence power density include:

- The number of transducers installed.

- The amplitude of ultrasonic waves.

- The depth and composition of the cleaning solution.

3. Temperature Control and Stability

Temperature plays a crucial role in ultrasonic cleaning effectiveness. Higher temperatures reduce the viscosity of cleaning solutions, improving cavitation efficiency. However, excessive heat can degrade transducer materials and shorten lifespan. Industrial ultrasonic cleaners often incorporate:

- Thermal sensors for real-time temperature monitoring.

- Cooling systems to prevent overheating.

- Adaptive power control to maintain optimal operating conditions.

Innovations in Industrial Ultrasonic Transducer Technology

Advancements in ultrasonic transducer design continue to improve efficiency, reliability, and adaptability in industrial cleaning applications.

1. Multi-Frequency and Variable-Frequency Transducers

Modern industrial ultrasonic cleaners now feature transducers capable of operating at multiple frequencies, providing:

- Greater flexibility for cleaning a wide range of materials.

- Improved uniformity in cavitation bubble distribution.

- Enhanced adaptability to different contaminants and surface types.

2. Digital Control Systems for Precision Cleaning

Smart ultrasonic cleaning systems integrate digital control technology to automatically adjust transducer power, frequency, and cleaning duration based on real-time conditions. These systems offer:

- Consistent cleaning performance with minimal manual intervention.

- Lower energy consumption and reduced operational costs.

- Extended equipment lifespan through optimized usage.

Industrial Applications of Ultrasonic Transducers

Ultrasonic cleaning technology is widely utilized across various industries due to its efficiency, precision, and ability to clean complex geometries.

1. Automotive and Aerospace Component Cleaning

Industrial ultrasonic transducers help remove oil, grease, and carbon buildup from engine components, fuel injectors, and aerospace parts. The non-abrasive cleaning process ensures that intricate features remain intact.

2. Electronics and Semiconductor Manufacturing

Precision cleaning is essential in electronics production to remove flux residues, dust, and microscopic contaminants from circuit boards, sensors, and microchips without damaging sensitive components.

3. Medical Equipment Sterilization

Hospitals and laboratories rely on ultrasonic cleaners to sterilize surgical instruments, endoscopes, and dental tools. High-frequency ultrasonic transducers ensure thorough decontamination without compromising instrument integrity.

4. Metalworking and Industrial Maintenance

Ultrasonic transducers are used in manufacturing plants for cleaning welding tips, cutting tools, and molds. The technology enhances productivity by extending the life of critical components and reducing downtime.

The Future of Ultrasonic Transducers in Industrial Cleaning

As industries demand more efficient and environmentally friendly cleaning solutions, ultrasonic transducer technology is evolving to meet these needs. Future trends include:

- AI-Driven Optimization: Integration of artificial intelligence for real-time monitoring and adaptive cleaning cycles.

- Energy-Efficient Designs: Development of transducers with lower power consumption while maintaining high cleaning efficiency.

- Enhanced Durability Materials: Innovations in piezoelectric and magnetostrictive materials to extend transducer lifespan and performance.

With continuous advancements, ultrasonic transducers will remain a cornerstone of industrial cleaning, offering superior precision and efficiency for a wide range of applications.

References

- K. S. Suslick, “Applications of Ultrasound to Materials Chemistry,” Annual Review of Materials Science, vol. 28, pp. 295-326, 1998.

- M. J. W. Povey, Ultrasonic Techniques for Fluids Characterization, Academic Press, 1997.

- W. L. Nyborg, “Ultrasound Bioeffects and Cavitation,” Ultrasound in Medicine & Biology, vol. 27, no. 3, pp. 301-333, 2001.

- J. A. Gallego-Juárez and K. F. Graff, Power Ultrasonics: Applications of High-Intensity Ultrasound, Elsevier, 2015.

GranboUltrasonic

GranboUltrasonic