The Future of Precision Cleaning: Customized Ultrasonic Cleaning Machines

Browse Volume:57 Classify:Support

Understanding Ultrasonic Cleaning Technology

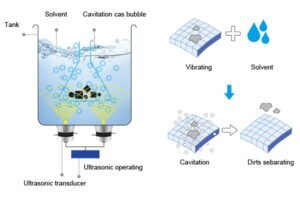

Ultrasonic cleaning technology has revolutionized the way industries handle precision cleaning tasks. By utilizing high-frequency sound waves, ultrasonic cleaners generate microscopic bubbles that implode upon contact with surfaces, effectively removing contaminants such as grease, dirt, oil, and even microscopic particles. This method is widely used across various industries, including healthcare, automotive, aerospace, and manufacturing.

Unlike traditional cleaning techniques that rely on manual scrubbing or harsh chemicals, ultrasonic cleaning provides a highly effective, non-invasive, and environmentally friendly solution. The ability to customize ultrasonic cleaning machines to meet specific industrial needs enhances their effectiveness, making them a crucial component in precision cleaning applications.

The Benefits of Customizing an Ultrasonic Cleaning Machine

Tailored Frequency and Power Settings

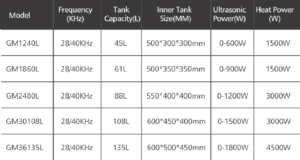

Different cleaning applications require varying frequencies and power levels. Low-frequency ultrasonic waves (20-40 kHz) are effective for heavy-duty cleaning, such as removing grease from automotive parts, while higher frequencies (80-200 kHz) are better suited for delicate instruments like medical tools and electronics. Customizing these parameters ensures optimal cleaning results without damaging sensitive components.

Adaptable Tank Sizes and Configurations

Industries have diverse requirements when it comes to the size and shape of components needing cleaning. Custom ultrasonic cleaners can be designed with tanks that accommodate specific dimensions, ensuring that all parts receive uniform cleaning. Whether it’s a large aerospace component or a set of intricate jewelry pieces, customized machines provide the flexibility needed for optimal performance.

Integration with Automation Systems

Many industries require seamless integration of ultrasonic cleaning systems into their existing production lines. Custom-built ultrasonic machines can include robotic arms, conveyor systems, and programmable logic controllers (PLCs) to enhance efficiency and consistency. Automation reduces human intervention, improving safety and reducing operational costs in high-throughput environments.

Specialized Cleaning Solutions and Multi-Tank Systems

Certain cleaning applications demand the use of specific cleaning agents. Customization allows for the selection of chemical-compatible materials for the tanks and ultrasonic transducers. Additionally, multi-tank systems can be incorporated to facilitate pre-washing, rinsing, and drying in a single setup, enhancing the cleaning process while maintaining efficiency.

Industries That Benefit from Customized Ultrasonic Cleaners

Medical and Healthcare Industry

Hospitals and medical device manufacturers require highly effective cleaning solutions to maintain hygiene and sterility. Customized ultrasonic cleaners ensure thorough removal of biological contaminants, reducing the risk of infections. They are used for cleaning surgical instruments, dental tools, and laboratory equipment without causing damage or corrosion.

Aerospace and Automotive Sectors

In the aerospace and automotive industries, precision cleaning is vital to maintaining component integrity and performance. Customized ultrasonic cleaning machines effectively remove carbon deposits, metal shavings, and lubricants from engine parts, gears, and hydraulic components, ensuring their optimal functionality and longevity.

Electronics and Semiconductor Industry

Electronic components are highly sensitive to contaminants, which can cause performance issues or complete failure. Customized ultrasonic cleaners with high-frequency settings ensure the safe removal of dust, flux residues, and microscopic debris from circuit boards, microchips, and connectors, improving their reliability.

Key Features to Consider When Designing a Customized Ultrasonic Cleaner

Material Compatibility

The choice of materials for the cleaning tank and ultrasonic transducers must be compatible with the cleaning solutions used. Stainless steel tanks with protective coatings can prevent corrosion and extend the machine’s lifespan.

Temperature Control and Degassing Functions

Temperature plays a crucial role in ultrasonic cleaning efficiency. Custom ultrasonic cleaners can be designed with adjustable heating elements to optimize the cleaning process. Additionally, degassing functions help remove dissolved gases from cleaning solutions, improving cavitation and cleaning performance.

Noise Reduction and Safety Features

High-powered ultrasonic machines can produce noise that affects workplace comfort. Customization options include soundproofing enclosures and insulated panels to minimize noise. Safety features such as auto shut-off mechanisms and overflow protection can also be integrated to enhance user safety.

Energy Efficiency and Environmental Considerations

Energy-efficient ultrasonic machines not only reduce operational costs but also align with sustainability goals. Custom-built models can incorporate energy-saving transducers, programmable timers, and eco-friendly cleaning solutions to minimize environmental impact.

Choosing the Right Manufacturer for a Customized Ultrasonic Cleaning Machine

Selecting a reliable manufacturer is crucial when investing in a customized ultrasonic cleaning system. Factors to consider include the manufacturer’s experience, technological expertise, and ability to provide after-sales support. A reputable manufacturer should offer consultation services to determine the ideal specifications for the intended application.

Collaborating with an experienced manufacturer ensures that the ultrasonic cleaner is tailored to industry-specific needs, providing maximum efficiency, durability, and long-term value. With the continuous advancements in ultrasonic cleaning technology, customized solutions will remain a key driver of innovation in precision cleaning applications.

References

- Mason, T. J., & Lorimer, J. P. (2002). Applied Sonochemistry: The Uses of Power Ultrasound in Chemistry and Processing. Wiley-VCH.

- Awad, S., & Ali, M. (2018). “Ultrasonic Cleaning in Industrial Applications: A Review.” Journal of Manufacturing Science and Engineering, 140(6), 1-10.

- Bussemaker, M. J., & Zhang, D. (2019). “Effectiveness of Ultrasonic Cleaning in Various Applications.” Ultrasonics Sonochemistry, 50, 201-208.

By leveraging customized ultrasonic cleaning machines, industries can achieve superior cleaning results while optimizing efficiency, sustainability, and cost-effectiveness. With the right design and manufacturer, ultrasonic cleaning technology continues to set new standards in precision cleaning.

GranboUltrasonic

GranboUltrasonic