The Essential Role of Industrial Cleaning: Enhancing Efficiency, Safety, and Sustainability

Browse Volume:53 Classify:Support

Industrial cleaning is a critical yet often overlooked aspect of modern manufacturing and production processes. It encompasses a wide range of activities aimed at maintaining cleanliness, hygiene, and operational efficiency in industrial environments. From factories and warehouses to power plants and refineries, industrial cleaning ensures that equipment, facilities, and workspaces remain free from contaminants, debris, and hazardous substances. This article delves into the concept of industrial cleaning, its significance, and the multifaceted benefits it brings to industries worldwide.

What is Industrial Cleaning?

Industrial cleaning refers to the specialized processes and techniques used to clean and maintain industrial facilities, machinery, and equipment. Unlike routine household cleaning, industrial cleaning involves handling complex systems, heavy machinery, and potentially hazardous materials. It requires specialized equipment, trained personnel, and adherence to strict safety and environmental regulations.

The scope of industrial cleaning is vast, ranging from removing grease and oil from machinery to decontaminating hazardous waste sites. It also includes cleaning ventilation systems, storage tanks, and production lines. The methods used can vary significantly depending on the industry, the type of contaminants involved, and the desired outcomes. Common techniques include pressure washing, chemical cleaning, abrasive blasting, and ultrasonic cleaning.

The Importance of Industrial Cleaning in Modern Industries

Industrial cleaning plays a pivotal role in ensuring the smooth operation of industrial facilities. Its importance can be understood through several key aspects:

1. Operational Efficiency: Clean machinery and equipment operate more efficiently. Dirt, dust, and debris can cause wear and tear, leading to mechanical failures and downtime. Regular cleaning helps prevent these issues, ensuring that production lines run smoothly and efficiently.

2. Safety and Compliance: Industrial environments often involve hazardous materials and processes. Accumulated contaminants can pose serious safety risks, including fires, explosions, and exposure to toxic substances. Industrial cleaning helps mitigate these risks, ensuring compliance with safety regulations and protecting workers’ health.

3. Product Quality: In industries such as food processing, pharmaceuticals, and electronics, cleanliness is directly linked to product quality. Contaminants can compromise the integrity of products, leading to defects, recalls, and reputational damage. Industrial cleaning ensures that production environments meet the highest hygiene standards.

4. Environmental Sustainability: Proper industrial cleaning practices help reduce environmental impact. For example, cleaning wastewater before discharge prevents pollution, while removing oil spills minimizes ecological damage. Sustainable cleaning methods, such as using biodegradable cleaning agents, further enhance environmental benefits.

Key Techniques and Technologies in Industrial Cleaning

The field of industrial cleaning has evolved significantly, with advancements in technology and methodology. Here are some of the most widely used techniques:

1. High-Pressure Water Jetting: This method uses high-pressure water streams to remove stubborn contaminants like grease, rust, and scale. It is particularly effective for cleaning pipelines, tanks, and heavy machinery.

2. Abrasive Blasting: Also known as sandblasting, this technique involves propelling abrasive materials at high speeds to clean surfaces. It is commonly used for removing paint, rust, and corrosion from metal surfaces.

3. Chemical Cleaning: This method uses specialized chemicals to dissolve or dislodge contaminants. It is often employed in industries where precision cleaning is required, such as pharmaceuticals and electronics.

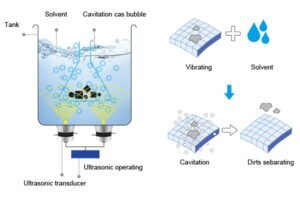

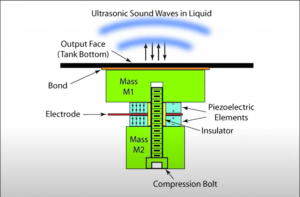

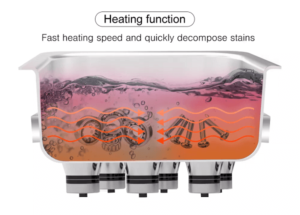

4. Ultrasonic Cleaning: Ultrasonic cleaners use high-frequency sound waves to create cavitation bubbles in a liquid solution. These bubbles implode, generating intense energy that removes contaminants from delicate parts and components.

5. Dry Ice Blasting: A relatively new technique, dry ice blasting uses solid CO2 pellets to clean surfaces. It is non-abrasive, non-conductive, and leaves no residue, making it ideal for sensitive equipment.

The Economic Impact of Industrial Cleaning

Investing in industrial cleaning yields significant economic benefits for businesses. While the upfront costs of equipment and labor may seem substantial, the long-term savings far outweigh these expenses. Here’s how:

1. Reduced Downtime: Regular cleaning prevents equipment breakdowns and extends the lifespan of machinery. This reduces the frequency of repairs and replacements, minimizing downtime and associated costs.

2. Energy Savings: Clean equipment operates more efficiently, consuming less energy. For example, removing scale from boilers and heat exchangers improves heat transfer, reducing energy consumption.

3. Regulatory Compliance: Non-compliance with safety and environmental regulations can result in hefty fines and legal liabilities. Industrial cleaning helps businesses avoid these penalties by maintaining compliant operations.

4. Enhanced Productivity: A clean and organized workspace boosts employee morale and productivity. Workers can perform their tasks more efficiently in a clutter-free environment.

Industrial Cleaning and Sustainability

As industries worldwide strive to adopt sustainable practices, industrial cleaning has emerged as a key contributor to environmental stewardship. Here’s how:

1. Waste Reduction: Advanced cleaning techniques, such as dry ice blasting and ultrasonic cleaning, generate minimal waste compared to traditional methods. This reduces the environmental footprint of cleaning operations.

2. Water Conservation: Many modern cleaning methods, such as high-pressure water jetting, use water more efficiently. Additionally, closed-loop systems recycle water, further conserving this precious resource.

3. Eco-Friendly Cleaning Agents: The use of biodegradable and non-toxic cleaning agents minimizes environmental harm. These agents break down naturally, reducing pollution and protecting ecosystems.

4. Energy Efficiency: Clean equipment operates more efficiently, reducing energy consumption and greenhouse gas emissions. This aligns with global efforts to combat climate change.

Challenges and Future Trends in Industrial Cleaning

Despite its many benefits, industrial cleaning faces several challenges. These include the high costs of advanced cleaning technologies, the need for skilled labor, and the complexity of cleaning large-scale industrial facilities. However, ongoing advancements in automation, robotics, and artificial intelligence are poised to address these challenges.

1. Automation and Robotics: Automated cleaning systems and robots are increasingly being used to perform repetitive and hazardous cleaning tasks. These technologies improve efficiency, reduce labor costs, and enhance safety.

2. Smart Cleaning Solutions: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) enables real-time monitoring and optimization of cleaning processes. Smart sensors can detect contamination levels and trigger cleaning cycles as needed.

3. Sustainable Innovations: The development of eco-friendly cleaning agents and energy-efficient cleaning equipment continues to drive sustainability in the industry. Future trends may include the use of renewable energy sources and zero-waste cleaning methods.

4. Customized Cleaning Solutions: As industries become more specialized, the demand for tailored cleaning solutions is growing. Companies are developing customized cleaning protocols to meet the unique needs of different sectors.

The Human Element in Industrial Cleaning

While technology plays a crucial role, the human element remains indispensable in industrial cleaning. Skilled workers are needed to operate advanced equipment, assess cleaning requirements, and ensure compliance with safety standards. Training and education are essential to equip workers with the knowledge and skills required for effective cleaning.

Moreover, fostering a culture of cleanliness within organizations is vital. Employees at all levels should understand the importance of maintaining a clean and safe work environment. This collective effort enhances overall operational efficiency and contributes to the success of the business.

References

1. Smith, J. (2020). *Industrial Cleaning Techniques: A Comprehensive Guide*. Industrial Maintenance Press.

2. Johnson, L., & Brown, R. (2019). *The Economic Impact of Industrial Cleaning*. Journal of Industrial Engineering, 45(3), 234-250.

3. Green, T. (2021). *Sustainability in Industrial Cleaning: Trends and Innovations*. Environmental Science and Technology, 56(7), 789-805.

4. Patel, S. (2018). *The Role of Automation in Modern Industrial Cleaning*. Robotics and Automation in Industry, 12(4), 112-130.

5. White, E. (2022). *Health and Safety in Industrial Cleaning: Best Practices*. Occupational Safety and Health Journal, 34(2), 45-60.

By understanding the concept and significance of industrial cleaning, businesses can unlock its full potential to enhance efficiency, safety, and sustainability. As industries continue to evolve, the role of industrial cleaning will only grow in importance, shaping the future of manufacturing and production.

GranboUltrasonic

GranboUltrasonic